SprayBot - a Robotic Spray Booth for the Automatic Painting of Bodyworks

Current body shops offer repairing and painting services for damaged cars/bikes. For this purpose, they boast modern equipment, among which traction, hydraulic and/or pneumatic benches, equipped with universal templates, through which body parts, chassis, axles and bridges are straightened out. Once the component is repaired, it is subject to the painting phase. Most of the times, this process is still hand made and based on the ability and experience of the operator. The client’s satisfaction, and therefore the business success of the workshop, is attained when the repaired and painted component looks as the original one as much as possible, after the industrial painting. Therefore, the manual skills of the operator are critical, and he must be highly qualified. In order to attain the best result, the operation is carried out inside technologically advanced booths, inside the workshop, equipped with systems that maintain and control the environmental parameters and reduce dusts, air flows and electrostatic charges. The paint drying process always takes place inside these booths by using suitable lamps. The operator works in an uncomfortable environment and the result of the operation is too subjective.

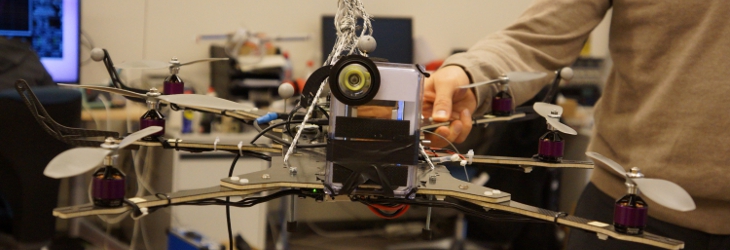

The objective of SPRAYBOT is to demonstrate that a robotic system, of affordable cost for the small/medium workshop, is able to carry out the painting phase improving the quality of the service with a reasonable investment.

The project aims to innovate the painting process in small/medium body shops, introducing automation in a process which still depends considerably on the human operator. In addition it could open new market sectors for the promoting companies and for the robot equipment providers. It will allow the exchange of knowledge between the industrial and academic sector thus strengthening their synergies and will be able to boost the development of new products and production processes.

|

|

| Size | Modified | |

| SprayBot.png | 401 KB | 2013/01/29 |

| Varnishing_1_lowres.jpg | 67 KB | 2013/01/29 |

| Varnishing_2_lowres.jpg | 76 KB | 2013/01/29 |