EASYPRO - Accurate Manual Guided robot programming

While static robot programs may be sufficient for high volume part manufacturers, they are not adequate in one-off or small-batch manufacturing. The result is that industrial robots are hardly ever used for small- batch and one-off manufacturing.

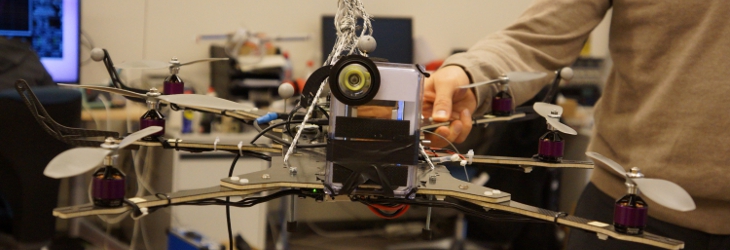

The objective of this experiment is to facilitate robot programming by combining hand guided end-effector rough movement planning and 3D visual servoing based accurate trajectory following.

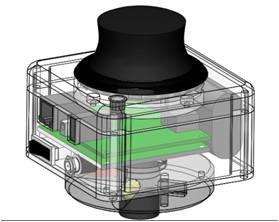

To integrate a breakthrough programming approach combining a ‘universal’ Manual Guidance Device (MGD) for a fast, intuitive but rough tool path programming, will be integrated with a 3D visual servoing approach to adjust the obtained trajectories and to allow accurate end-effector positioning by automatic on-line correction of Tool Central Point (TCP) path. The user decides the distance between the end-effector and the part on top of which the application has to process, the orientation with respect the part, the type of correction and any other parameter relevant for the process.

In EASYPRO this new approach will be tested and validated in a real production scenario by integrating it in a Laser Cladding process, an innovative method of depositing a material on top of other. Robots are used to this aim, but their use requires programming the trajectory manually. This hard, time-consuming task will be dramatically optimized by using the EASYPRO approach.

|

|

|

| Size | Modified | |

| EASYPRO_Robot.jpg | 78 KB | 2011/10/18 |

| Manual Guiding Device.jpg | 11 KB | 2011/10/18 |