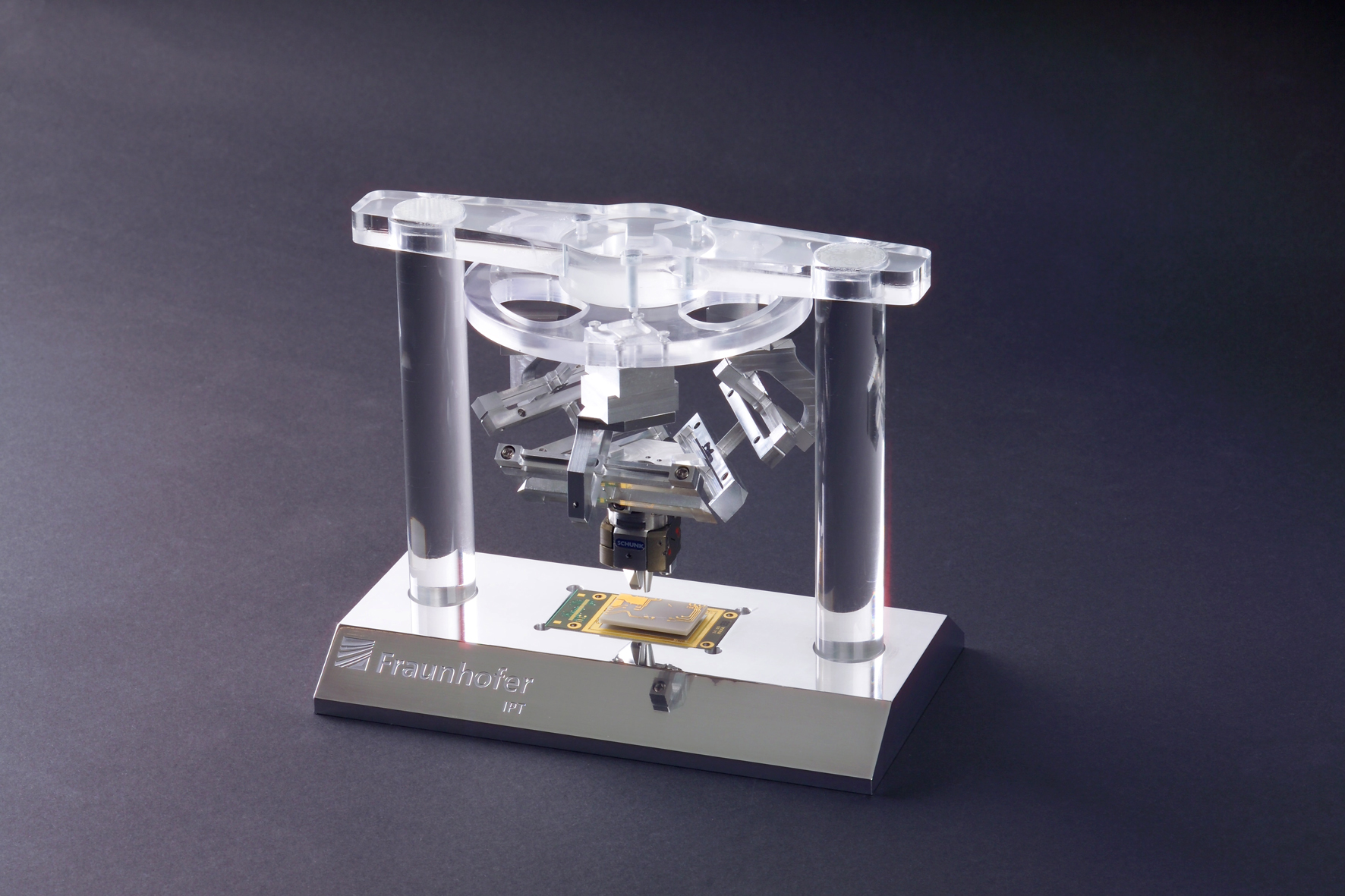

flexprass - Flexible Precision Assembly with Mobile Robots

The integration of human workers and their creativity with mechanical precision allows the efficient production of high-tech products in small lot sizes. In the flexprass experiment the partners SCHUNK and Fraunhofer IPT combine human-friendly modular industrial desktop robotics with high-precision equipment. This will make it possible to setup a flexible precision assembly system for highly demanding products such as laser-systems. Programming efforts and planning activities can be reduced to a minimum in this human-robot co-worker scenario because the complexity of manipulation can be handled by the experience of the human worker. Compared to conventional scenarios, where plain manual assembly plays a major role, this approach offers improved working conditions, reducing the cognitive efforts of the human worker. Yet, it makes the overall process sustainably more efficient and even improves product quality.

|

|

| Size | Modified | |

| Commander 6.jpg | 1.00 MB | 2011/10/17 |