Nov 30, 2012 , by

Public Summary Month 11/2012

The tripod has been assembled and was put to operation successfully including the clamping mechanism of the protection module. The animations have been extended to show the tip and tilt rotational motion. Additionally, a video was taped showing similar movements in reality.

All objectives of the experiment have been achieved.

Oct 2, 2012 , by

Public Summary Month 9/2012

Image processing routines for automated lens pickup have been implemented. That includes routines for calibrating camera coordinate systems with the robot base coordinate system and for finding out translational and rotational offsets between robot TCP and target camera view (camera attached to robot TCP or to micromanipulator).

Sensitivity analysis (power plot) regarding tipping and tilting of resonator mirror has been implemented with the micromanipulator performing steps of five millidegrees each 50 milliseconds. The limits of the system have not been touched yet.

Jul 30, 2012 , by

Public Summary Month 7/2012

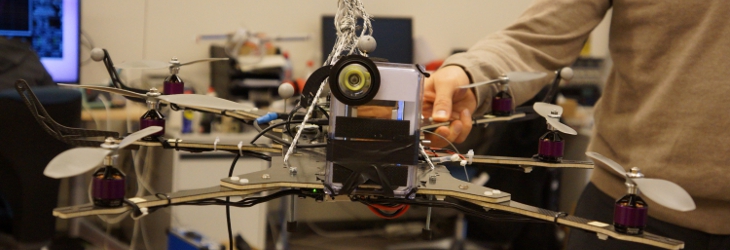

The construction of the tripod micromanipulator has been finished. The concept includes high precision motion resolution for tip and tilt angles as well as Z-direction, mechanical protection, and integrated machine vision. Image processing routines have been implemented for identifying lenses of different types and to “auto-focus” the robot above the optical components. The information from image processing can be used to pick up optical components autonomously.

May 31, 2012 , by

Public Summary Month 5/2012

For operating the robot and the peripherals a graphical user interface (GUI) has been implemented. The GUI offers functionalities for teaching robot poses, for commanding peripheral devices, and to save and load programs. Using the GUI a tool exchange procedure was programmed.

The motion resolution of the micromanipulator was analyzed using a 3-beam-interferometer. Subject to the analysis was the motion resolution in tool-direction (Z-direction). Steps of 10 nm could be resolved by the hardware.

Mar 30, 2012 , by

Public Summary Month 3/2012

A camera for observing the working area of the precision manipulator “Commander6” was integrated for automated pick up of optical components.

For systematically designing tripod kinematics based on flexures for higher precision and step resolution a design methodology was worked out for realizing the design objective of a defined work space considering constraints and secondary design objectives.

First measurements of repeatability and dynamic behaviour such as overshoot were carried out with four laser tracers which allow precise measurements in a large workspace.