Aug 8, 2011 , by

Public Summary Month 7/2011

Progress of the ALEXA experiment

Task 1 – Technical concept

Concept of the ALEXA Robotic Arm In the first stage, the joint configuration and the links length of the 5-DOF ALEXA robotic arm were determined by optimizing the workspace. Here, all constraints (angular range of the joints, etc.) and conditions (load-case, etc.) were take into account.

Separating the robotic arm from drive system is a key feature of the ALEXA robot system, and should allow for good transportability. A tensing mechanism was designed that allows for the Bowden cables to be detached from the drive modules.

Concept of the Camera System and Visual Servoing The camera system for visually guiding the manipulator consists of two cameras: Camera A is mounted at the first link of the robotic arm (to detect relevant objects within the working area) and Camera B is mounted next the gripper (to pose the gripper). Since the ALEXA experiment is not concerned with object recognition, we will use markers to detect relevant objects.

Task 2 – Derivation of direct, indirect, and differential kinematics

Determination of kinematics The kinematic model of the ALEXA robotic arm consists of the solution of the direct, inverse, and differential kinematics. All solutions were determined in closed-form. Further, the equation of motion of the robotic arm was determined by following the Euler-Newton formulation.

Development of trajectories generator An algorithm for planning torque optimized paths and computing trajectories is still in progress.

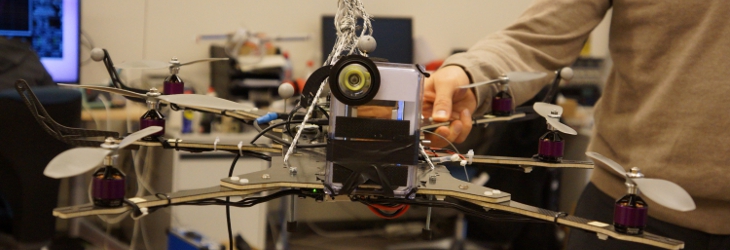

Task 3 – Construction of the robot system

Construction of a prototype The actuation of one cable-driven Robolink joint is currently being tested with an experimental setup whereby the Bowden cables are long and laid out in an unrestricted manner. Furthermore, a mechanism to detach and tense the Bowden cables was built-up as well.

Construction of the robotic arm To extend the workspace of the ALEXA robotic arm, our project partner Igus has modified its standard Robolink joint and the transits of the actuation ropes. Finally Igus will build-up the whole robotic arm by the beginning of August.

Construction of the compact drive system The construction of the compact drive system is in an early state. We have begun to design the drive bearings and the detachable tensing mechanism.