Jul 26, 2011 , by

Public Summary Month 7/2011

Task 2: Implementation and integration of adaptive arm and platform controllers

Activities performed:

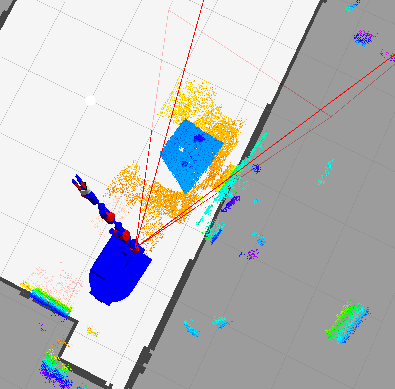

- Improvement of the mobile platform collision avoidance system using Kinect 3D sensors.

- Integration of the arm controller on the prototype and implementation of pressing button and turning knob actions on a real washing machine control panel.

Task 3: Implementation of diagnostic funtion

Activities performed:

- Application sensor data analysis: data collected from washing machines using the Scanning Laser Doppler Vibrometer (SLDV) mounted on InterAID Robot allows identifying abnormal vibration on the front panel. Further analysis is required to identify other possible malfunctionings.

- Diagnostics strategy definition and implementation: using motorized mirrors and visual feedback is possible to position the spot of the SLDV mounted on InterAID Robot in order to compensate any small deviation from the stated measuring position and to improve the signal-to-noise ratio searching in a small area for the highest “quality” signal.

- User interface implementation: Washer Inspector GUI permits to easily describe the washing machine laboratory environment and define InterAID Robot’s trajectories and movements inside it.

May 27, 2011 , by

Public Summary Month 5/2011

Task 2: Implementation and integration of adaptive arm and platform controllers

Activities performed:

- Navigation considering environment modeling completed: 3D sensors are used to detect obstacles in the driving direction of the mobile platform; if an obstacle is inside the safety distance the navigation control stops the movement of the mobile platform.

- Arm control considering environment modeling completed: using arm internal sensors and 3D sensors self and environment collision avoidance are performed; arm planner is able compute a collision free trajectory to reach the target position.

- Integration on the prototype in progress: 3D sensors and arm basic software is installed on the prototype; their integration in the ROS environment is still in progress.

Mar 31, 2011 , by

Public Summary Month 3/2011

Task 1: Prototype integration

Activities performed:

- Electrical modification on the mobile platform

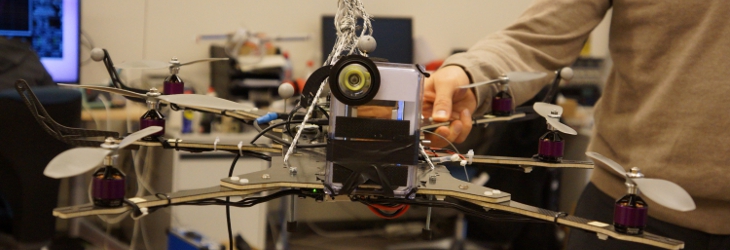

- Re-design and realization of mechanical supports for the measurement and 3D sensors

- Mounting of 3D sensors and robotic arm on the mobile platform

- Mounting of 7DOF robotic arm on the mobile platform

Task 2: Implementation and integration of adaptive arm and platform controllers

Activities performed:

- Definition and implementation of the communication protocol between LabVIEW and ROS

- Environment modeling completed

- Navigation considering environment modeling in progress

- Arm control considering environment modeling in progress