Aug 25, 2011 , by

Public Summary Month 8/2011

In view of a worldwide shortage of energy resources and an increasing concern about climate change, the research project dimRob focuses on a radically new approach for tomorrow’s building reality. dimRob studies the manifold amalgamation of architectural design and robotic fabrication and researches on the invention of novel technological solutions within the context of design, construction and fabrication. Through introducing mobile accessibility, cognitive skills and highly innovative scanning technology dimRob fosters the next logical step in robotic fabrication and addresses multiple potentials in making the robot operational.

Key to this approach is the underlying notion that robotic fabrication is traditionally embedded within the industrial environment where fixed positioning and constant conditions determine the robot’s life. However, extracted from this safe context in order to directly use it on the construction site, multiple issues arise – on one hand, for this purpose the robot has to be mobile and robust; it has to recognize its own position and to assemble new building elements within existing construction and material tolerances; on the other, it has to operate on human control and to react on visual instructions. This forms the basis for an innovative research approach and forms the empirical methodology of this project. In this regard, the first two phases of scientific investigation can be summarized as the following:

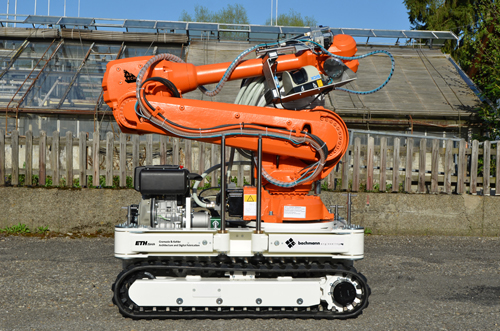

During the first work package of dimRob, not only the experiment set up could be successfully implemented and already used for a larger exhibition project (2011 Fabricate Conference, London) but also the additional hardware equipment could be fully integrated. Together with the industrial partner Bachmann Engineering AG a compact mobile track system with integrated raising jacks was developed and formed the basis for mounting the ABB IRB 4600 (2.55) industrial-robot on it. The ABB robot not only provides with a wide operational range but also offers low weight. Moreover, in order to use the robot unit on a construction site, the boundary dimensions were limited to the size of a standardized door frame. This also allowed for a compact transport unit. To further advance the operationability, a diesel engine was integrated for the transport of the robot unit.

Further, the robot unit was equipped with two vacuum grippers in order to use it for particular (additive) construction purposes. This enabled taking single bricks at high speed and to position them with high precision throughout the operational building space of the robot unit. In order to have a compact mobile unit, the vacuum pump for the gripper was installed on the back of the robot. In addition, a powerful laser measurement system (Sick LMS 500) was installed on the robot’s arm. It guarantees the detection of tolerances on the construction site and emphasizes further research in this field. Next to the hardware setup, also the development of software played a major role in this phase of development of dimRob. For the buildup of individually articulated masonry, a plug in for an existing CAD software was programmed. This enabled to export data directly from the design to the programming language of the robot. In the next phase of development, this tool will be further refined and adapted to more efficient workflows and broader applications.

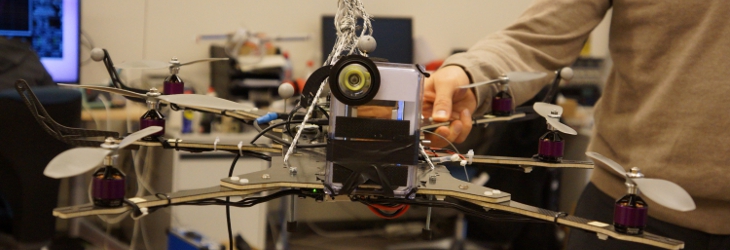

The second phase of investigation is determined by developing a cognitive strategy for self-positioning the robot. As the unit is planned to be used on construction site it has to operate within partly unknown contexts and has to freely orientate in three-dimensional space as well as to recognize obstacles or human workers. This is enabled by the already implanted scanning technology and will be further developed by programming spatial feedback operations that compare collected data to already existing data of the site. Here, the 2011 Fabricate Conference in London provided with a first useful opportunity to test this scenario and allowed for constructing an additive assembly of individual wooden building-elements based on an intelligent feedback strategy.