Aug 16, 2011 , by

Public Summary Month 6/2011

Experiment description

Countless everyday life products such as electronic equipment or complex parts of the automobile industry suffer from physical or mechanical strain like vibration and shock.

The product design has to take all these stress factors into account to guarantee the full function of a product during shipping and final usage.

It is indispensable to test and measure all these stress factors beforehand. Usually those sorts of vibration tests are carried out on special vibrating units or shaking platforms.

Electric shakers are being used mainly for higher vibration frequencies in one dimension.

To test for more complex movement hydraulic multi axis motion units are commonly used, each custom build for a specific vibration pattern.

To overcome this drawback one could use a hexapod instead, which is capable of complex movements in all 6 degrees of freedom and is easy to reconfigure.

If a different pattern is needed one has only to change the trajectory of the hexapod.

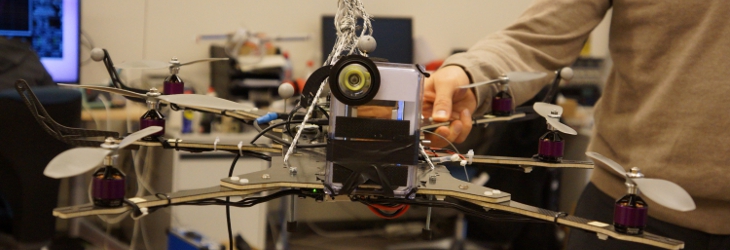

In general a hexapod consists of a base and a plate connected through 6 actuators each independent of each other and capable of push and pull forces.

The latest realization at JKU uses pneumatic muscles which are only capable of contraction force thus it wouldn’t be possible to apply a load.

To compensate this a centered spring for expansion force is integrated in the design of the muscle hexapod.

The spring is highly nonlinear and not well specified. But the given design is light weight, easy to transport and environmentally safe,

no oil or chemical spill like hydraulic systems.

The aim of the project is to determine if a test load put on the hexapod changes in behavior i.e. to sense if something gets loose or even breaks.

In Task 1 the dynamical model has to be elaborated and a simulation of the hexapod computed.

The computation of the equation of motion is done in Maple and integrated via a dynamic model package (Simcode2) to Matlab Simulink as a C-code S-function.

A virtual reality model is used to visualize the simulation results as well as various scopes to investigate the model behavior.

It is possible to input the actuator force into the model together with a disturbance force and torque stated in the inertial system.

The output of the simulation is the actuator position together with the velocity.

The simulation result shown in this figure displays the output of a sinusoidal phase shifted actuator force input.

The next step is to investigate the behavior with changing connection parameters for body P and B and how it will affect the simulation results.

This model can now be used for further investigation on control and observer structures.

State month 6

A complex dynamical model is derived with the opportunity to simulate changing load distribution and load failure with different scenarios.

The simulation was implemented in Matlab Simulink and visualized by a vrml model to investigate the load model behavior.

Furthermore implementations to recognize load failure can now be tested safe, easy and fast.

The theoretical model of the hexapod can be used for a model based observer structure.