May 31, 2011 , by

Public Summary Month 5/2011

Within the last two months we have been continued the work on the tasks safe manipulation in industrial environments, magnetic localization of mobile manipulators & tracking of boxes and integration and adaptation of the mobile platform.

The basis for preparing a safety concept for KANMAN’s manipulator are ISO EN 10218-1:2006 for the robot itself and ISO EN 13849 for the robot’s control. The standards are harmonized with the Machinery Directive. The current concept developed, pursues the use of a safety controller by Schmersal ELAN to securely monitor robot. The safety controller supervises the communication (CAN Bus) between robot control and robot, additionally the encoder signals will need to be monitored separately. In case of a failure either of the robot or the robot control, the safety controller is able to put the system into a safe state (stop category 0 or 1), according to ISO 13850 and IEC 60204. The integration of the safety controller will allow a safely supervised position, a safely reduced speed, work area monitoring, emergency stop and operational stop (stop category 2).

According to the magnetic localization first tests with the linear array of 9 sensor modules with 3 AMR sensors per module shows a deficient sensor characteristic. To improve the performance of the Sensor modules we built up a calibration and measuring place to measure noise, linearity, angularity and the slope of the sensor signals. The whole prototype (magnetic localization electronics for navigation) according to deliverable D KANMAN.2 is almost finished.

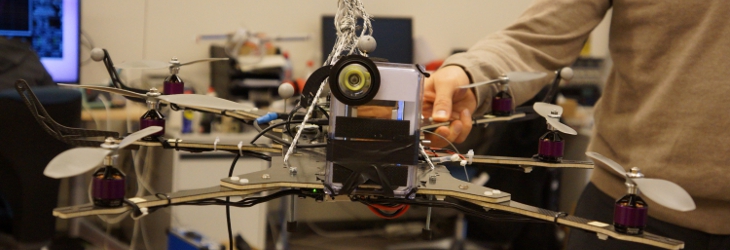

Finally, we have designed the mechanical bodywork for the first KANMAN prototype consisting of three metal plates. It includes a lithium polymer battery, necessary electronic components, an industrial PC, fixings for the the robot arm, the display and two boxes, and two drive units with motors, gears, couplings, and wheels. It was partly set up.

Apr 1, 2011 , by

Public Summary Month 3/2011

We have performed various test measurements at several places to investigate the existent magnetisable parts the in the floor. We have extended the SCITOS' control software in a way that the current magnetic data and their history can be pictured. To increase the resolution we have developed and realized a measuring hardware based on three AMR sensors capable of being integrated in a bus and connected to a master module. A new prototype was finished and successfully integrated in a SCITOS mobile robot platform.

Dissemination activities:

- 4th International Expert Days Service Robotics at SCHUNK facilities in Germany on Feb, 23rd/24th 2011: Presentation of the demonstrator and a magnetic ruler

- 11th Symposium Magnetoresistive Sensors and Magnetic Systems in Wetzlar/Germany: Talk "Magnetic Field Sensing for Fast Motion Tracking and Robotic Navigation with Ambient Magnetic Fields"

KANMAN at the 4th International ExpertDays Service Robotics

Jan 31, 2011 , by

Public Summary Month 1/2011

The KANMAN experiment develops an application where a mobile manipulator will support a Kanban production process by taking care of the flow of materials. In the first four months we discussed our approach with production experts and defined and prioritised three use cases.

Furthermore, we have realized the set-up of a mobile platform and have successfully integrated the magnetic sensor prototypes in a mobile robot platform. The following figure shows example data sets recorded during the movement of a robot platform in an example industrial environment for way of about 10 m. The figures show a magnetic map based on the average magnetic field (green = 0, red = positive, blue = negative). The comparison between the way out (left) and way back (right) underlines the good reproducibility. We are currentling working on the integration of these sensor information in the localisation map of the robot.